Overview | Testing | Extreme Conditions | Modelling & ML | Pilot Testing

Pilot Testing Facility

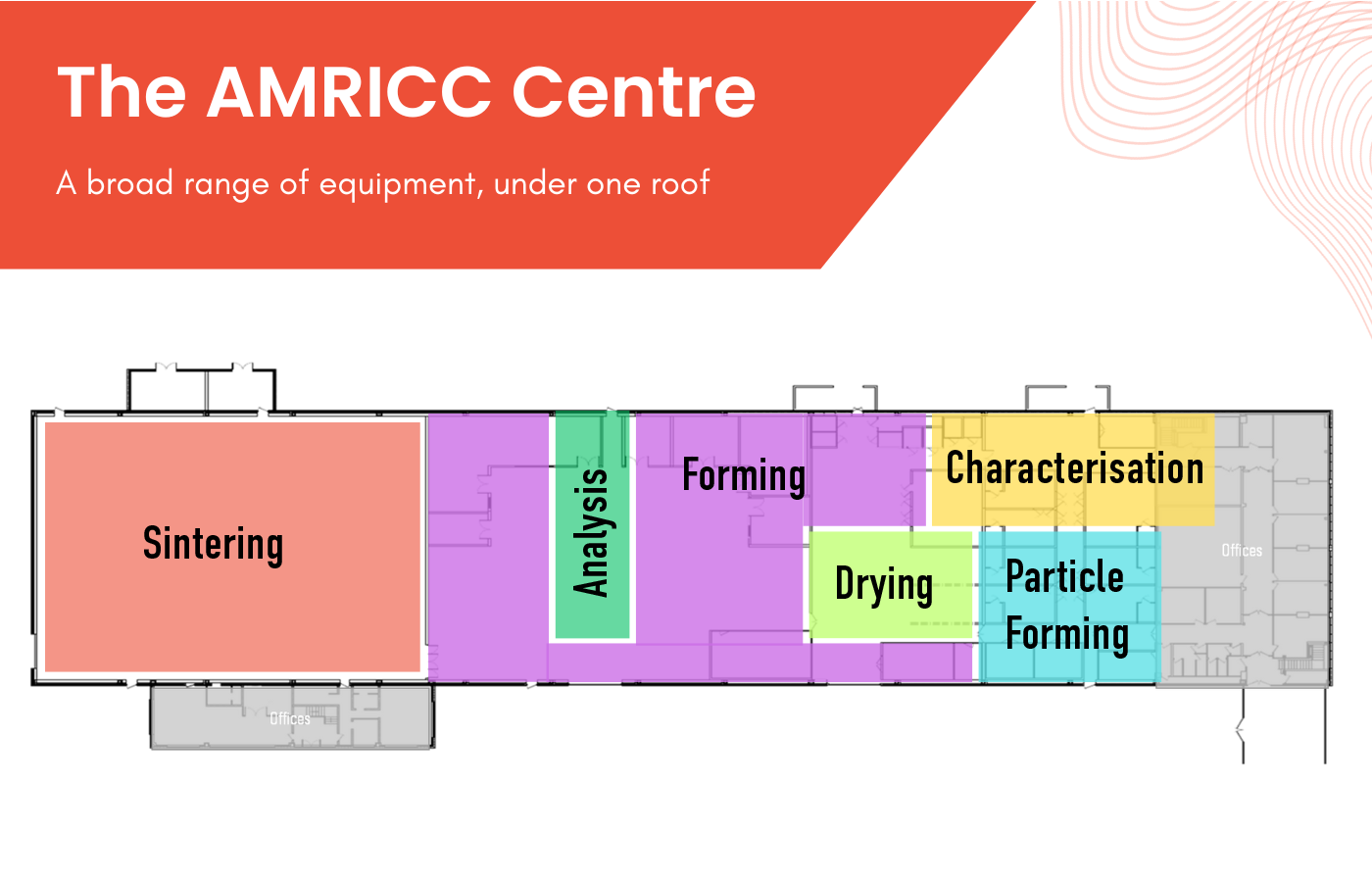

Our prototyping and pilot-scale facilities enable us to move products, processes, and technologies from the laboratory and development stage to pilot- and production-scale, providing real industrially relevant capability.

Our dedicated team of scientists and engineers has extensive expertise in production process requirements and translating these into clearly-defined scale-up projects.

We have a wide range of pilot processes, following typical manufacturing flow from raw material characterisation to finished product analysis.

Our facility layout reflects the order of processes for ceramics manufacturing, from right to left.

Pilot-scale facilities for powder processing and prototyping are also available.

Commercialisation

of products and processes is what AMRICC is all about – our prototyping and

pilot-scale facilities form the backbone of this. And it's all available

without needing to take your existing production offline.

The

AMRICC Centre’s areas of development activity are many and varied:

manufacturing process optimisation, additive manufacturing of ceramics, lower

energy manufacturing technologies, and the use of alternative fuels on the

pathway to Net Zero.

The

AMRICC Centre can assist companies with virtually any stage of product

development relating to ceramic materials, including:

- Early prototyping and development trials

- New manufacturing processes

- Manufacturing process improvement

- Small scale trials of ‘standard processes’

- Production of trial batches

Contact us here to discuss your requirements, arrange a visit, and discover our full range of equipment.